| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | LIANDA |

| Model Number : | LDHD-200 |

| Certification : | CE,SGS,ISO9001 |

| Payment Terms : | T/T, L/C, Western Union |

| Delivery Time : | 40 working days |

Plastic Hopper Dryer

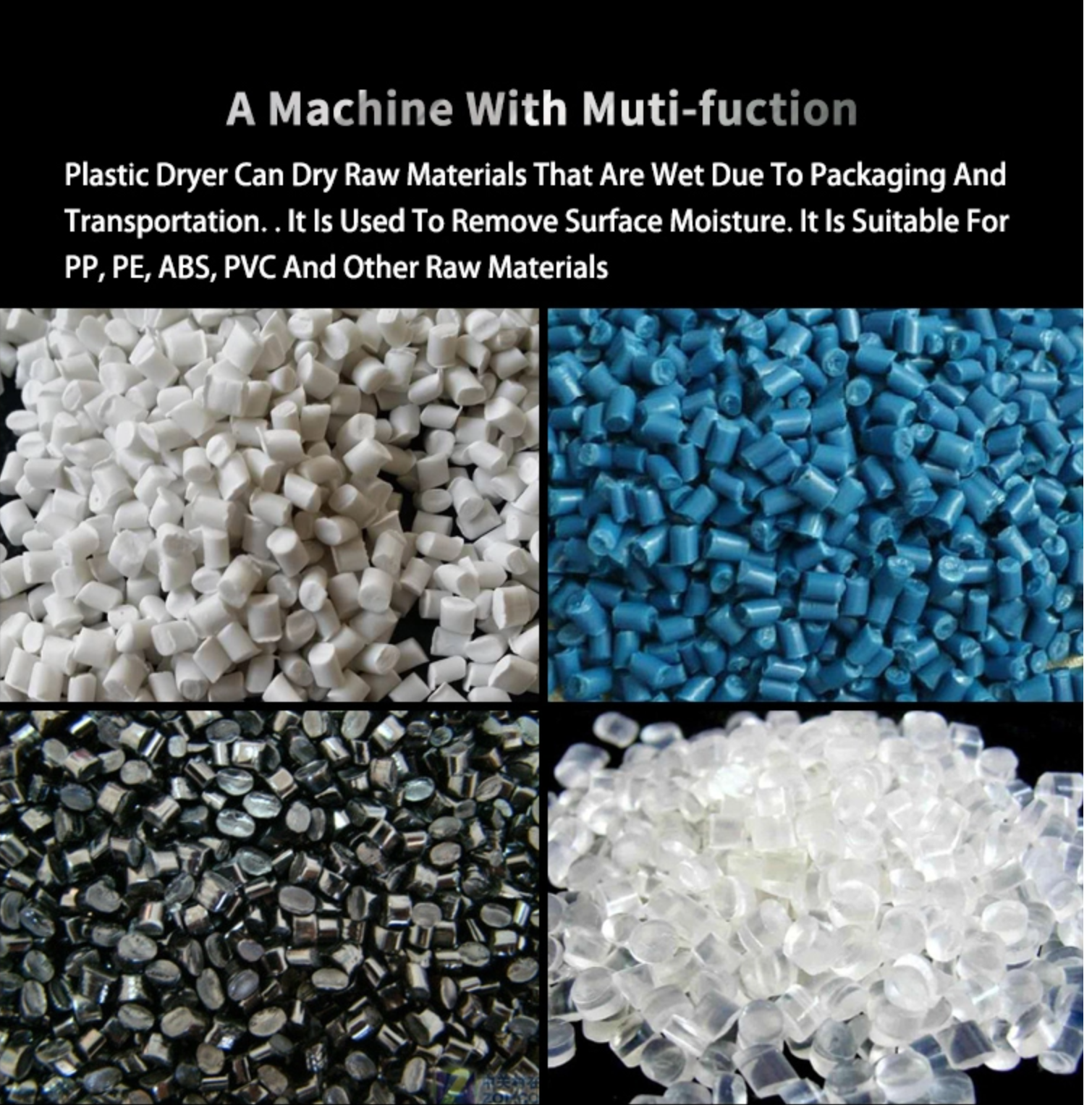

Hot air plastic hopper dryer are used to dry raw materials which are re-moisture due to packaging, transportation or recycling. The plastic hopper dryer can be used with injection molding machine or various plastic shaping machine. It will save energy by 27-65% and it will avoid the plastic raw material second moisture absorption after dried while it is placed on the inlet of main machine. The hopper dryer will shorten the injection time and improve the quality of finished product.

Hopper dryer Model

| Model | Capacity KGS | Heating power KW | Blower W | Dimension MM | Bottom size (KxKxD)MM |

| LD-G12KG | 12 | 1.8 | 85 | 640*440*740 | 110*110*Φ40 |

| LD-G25KG | 25 | 3.5 | 135 | 800*420*850 | 150*150*Φ73 |

| LD-G50KG | 50 | 4.5 | 135 | 900*600*950 | 160*160*Φ73 |

| LD-G75KG | 75 | 5.5 | 210 | 900*600*1050 | 160*160*Φ73 |

| LD-G100KG | 100 | 6.5 | 215 | 1000*650*1050 | 177*177*Φ81 |

| LD-G150KG | 150 | 9 | 320 | 1300*700*1100 | 177*177*Φ81 |

| LD-G200KG | 200 | 12 | 320 | 1350*800*1400 | 200*200*Φ83 |

| LD-G300KG | 300 | 15 | 320 | 1300*900*1550 | 230*230*Φ114 |

| LD-G400KG | 400 | 18 | 410 | 1400*950*1600 | 280*280*Φ120 |

| LD-G600KG | 600 | 21 | 1030 | 1550*1150*1850 | 281*281*Φ134 |

| LD-G800KG | 800 | 24 | 2200 | 1770*1180*2540 | 280*280*Φ135 |

Hot air plastic hopper dryer Advantages:

Hopper dryer structure drawing

Machine details | ||

| 1 | Adopt LCD display controller, new man-machine interface; |

|

Equipped with one-week timing automatic Start/OFF to save energy and be more convenience. | ||

| 2 | Adopt Siemens Electrical elements, the quality will be more stable |

|

| 3 | Precision die-cast aluminum housing with smooth surface and good thermal insulation performance |  |

| 4 | With visual material window, you can directly observe the internal raw materials | |

| 5 | Other detailed photos shown |  |

| ||

Application examples:

Plastic granulates /pellets Hopper dryer for Injection molding machine

PE PP ABS Hopper dryer

Plastic hot air dryer

Plastic material Hopper dryer

Hot-air plastic scrap hopper dryer

Air dehumidifying plastic scrap/pellet hopper dryer machine

1.Pre-sale: we given client the details technician offer etc

2.In-sales: we supply the details layout, installation instruction,

technician support for the clients

3.After sales: we arrange engineer to install the machinery and

training the workers for client

4.We have 24 hours team to solve the after sales problem

5.We have free spare parts with the machine

6.We supply long term spare parts for every customer

7.We always up date the new technology to every customer

HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped

with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by

inspecting personnel.

● Each assembly is in charged by a master who has working

experience for more than 20 years

●After all the equipment are completed, we will connect all the

machines and run the full production line to ensure the stable

running in customers' factory

AFTER-SALE SERVICE OF LIANDA MACHINERY!

● After finish the production, we will debug the production line,

take photos, videos and send them to customers via mail or instant

tools

● After the commissioning, we will package the equipment by

standard export package for shipment.

● According to the customer's request, we can arrange our engineers

to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will

form a after-sales team, online and off line, to follow the

customers' project.

|